Match made in heaven

Dear Andrea and the hiring team,

I recently came across the job posting Advanced Automation & Robotics Engineer and believe I would be a valuable addition to the team.

The role seems tailor-made to me, and I believe I could be the perfect fit for the team. You see, I come from an educational background as a Process and Innovation Engineer from DTU, providing me with a strong foundation in product development and user-centered design. On top of that I possess an extensive technical background compared to most process and innovation engineers. I have a personal background in mechanics and have been working for multiple years with electronics, industrial automation, and robots.

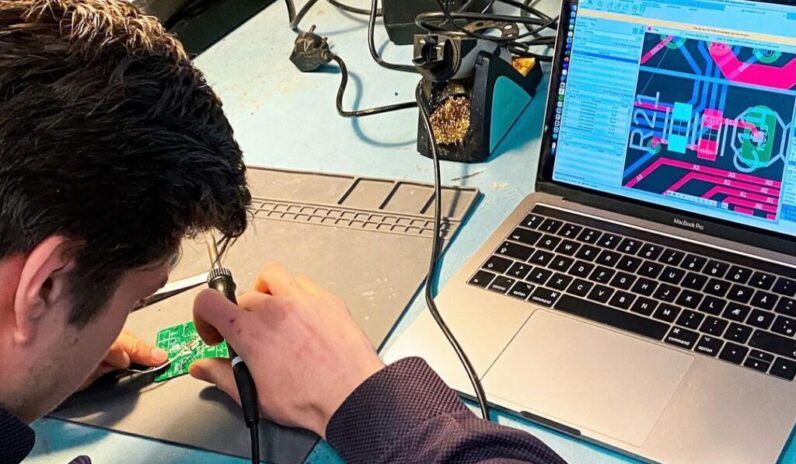

In addition to my formal education, I run my own ‘side-hustle’ focused on developing functional prototypes for customers – exactly what I understand you are searching for. I have a genuine interest in technology, allowing me to excel in 3D CAD design modelling using tools such as SolidWorks, Autodesk Inventor, or Fusion 360. I have combined more than 10.000 hours in 3D CAD programs. I have experience designing and overseeing the manufacturing of PCBs in large quantities and coordinated with Chinese suppliers. While my programming skills may not be at the level of a professional programmer, but they are above average, which is a strength when combining mechanics, electronics and software.

Me and my background

Regarding the Automation & Robotics Engineer position, I would like to highlight three key experiences that I believe align well with the requirements of the role.

Electrical Engineer at Seasony

At Seasony, I served as an electrical engineer for an innovative collaborative robot tasked with navigating vertical farms and handling logistical operations such as plant picking and harvesting. My responsibilities included designing the electrical systems, picking and procuring sensors that fit into the mechanical CAD work with the right quality and cost as well as meeting software implementation elements. Additionally, I took the lead on ensuring the safety compliance of collaborative robots, ensuring a secure environment for people working in proximity of the robot.

Mechanical Engineer at Hallam-ICS (MA, USA)

During my time at Hallem-ICS, I worked as a mechanical engineer for the pharmaceutical industry. My role involved designing cleanrooms for Pfizer, adhering to ISO classifications 8, 7, 5, or as per Novo’s terminology, classes D, C, B, and A. This experience provided me with knowledge of regulated industries, encompassing both room design and the WFI systems we developed. Knowing that I only saw the tip of the iceberg, I understand the mentality of the medicinal industry.

Prototype Developer at Roskilde University

For five years, and still running, I work on Tuesday afternoons at Roskilde University assisting individuals in our open workshop with developing prototypes.

I am helping with a wide range of tasks, including programming, electronics, CNC milling, 3D printing, laser cutting, and more to help people start a business, get a project finished or simply make a replacement part for their coffee pot.

These experiences have equipped me with a diverse skill set, combining electrical and mechanical expertise with hands-on involvement in robotics, safety protocols, cleanroom design, and open workshop activities. I am confident that these experiences make me well-suited for the Automation & Robotics Engineer position.